Royal Posthumus. Reliable, progressive and purposeful. For more than 145 years. |

|

|

Royal Posthumus: stamps, name plates and name badges. |

|

|

One of the largest European players In Europe, Royal Posthumus is one of the largest companies in the field of stamps, nameplates and engravings. With more than 60 employees we are active in the Benelux, France, Germany, Switzerland, Austria, Italy and the UK, with offices in Amsterdam, Eupen (Belgium) and Aachen (Germany). |

|

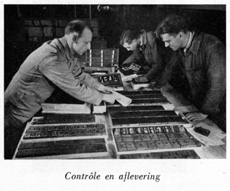

Successful across generations Royal Posthumus has always been a family business. On 1 June 1865, Jan Daniël Posthumus started a company in Amsterdam (now Damstraat), specialising in the manufacture of metal stamps and high quality engravings. At the beginning of the 20th century his sons Willem and Louis took over the business. In 1939 they sold the company to Johannes van der Plaats, who took up his post as director three years later. Thirty years later, in 1969, he hands over the management to his son Taco. In 2006, the third generation of Van der Plaats joined with grandson Nicholas. |

|

Royal since 1920 In 1920 the company acquired the designation Royal and is called Koninklijke Fabrieken Posthumus. The private secretary of Queen Wilhelmina, Baron F.M.L. van Geel, writes about this: "I have shown your so excellently executed weapons to various heads of departments of the royal court; your address has been kept and I have no doubt that you will be contacted in case of any new orders. Your work does indeed fully deserve this.” After 1945, all companies that were allowed to call themselves Royal before the war are judged whether they still deserve this predicate. Posthumus regains this thanks in part to their multifaceted support for the Resistance. |

|

Advanced technology at home |

|

|

CNC engraving Contrast technology Hand-engraving Laser-engraving and polymerisation UV printing technology Vulcanisation Also visit De Stempelplaats for more products and ideas. |

|

- 150 years of experience

- Directly from a Dutch factory

- Widest range of products

- £7.50 Delivery

- Free shipping from £75.-

Scroll to top